Marking systems and equipment

Marking systems and equipment

Marking units and transport packaging with labels, ink, or lasers is an area of application for which we can provide a wide range of solutions, such as robot labelling of roll and pallet packages with large A3 labels, and smaller stickers for Print & Apply automation.

Sheeting plant pallet labelling, sheet counting, and ream marking

We deliver labelling systems for paper and board factories’ sheet packing lines, which often have a laser printer. A thermal transmission printer is also suitable for the task. Labels are attached either to the outer surface of the package or to the sheet stack before wrapping in packing plastic, so the label is attached to the topmost sheet and hangs down the side of the stack. The label is also well-protected under the plastic wrap and remains intact even after the wrap is removed.

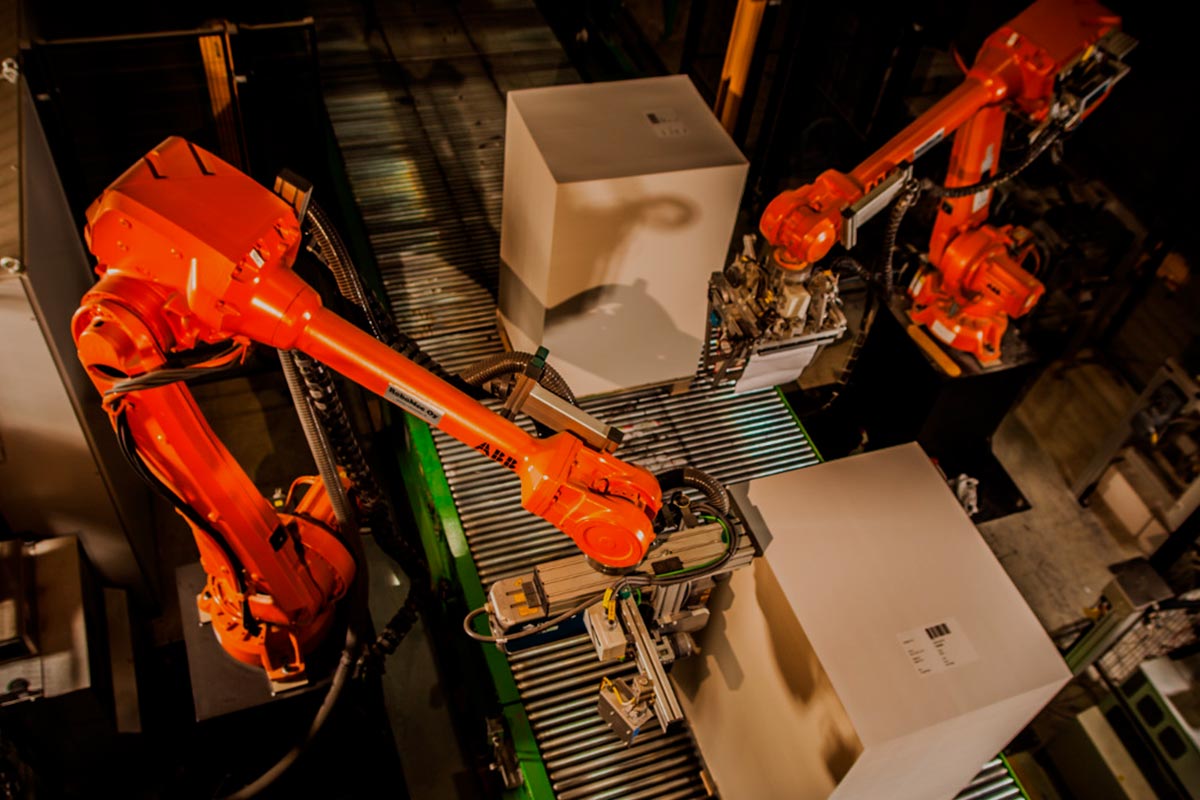

We also deliver robot-based systems in which the number of sheets in a stack is counted by a robot and X marks are burnt into the side of the stack as ream markings using a laser marker.

Robotic labelling of roll packages at paper factories

Capacity of up to 120 rolls per hour with two labels, pre-printed label and black-and-white printing. The printer can be either a laser printer or a thermal transmission printer.

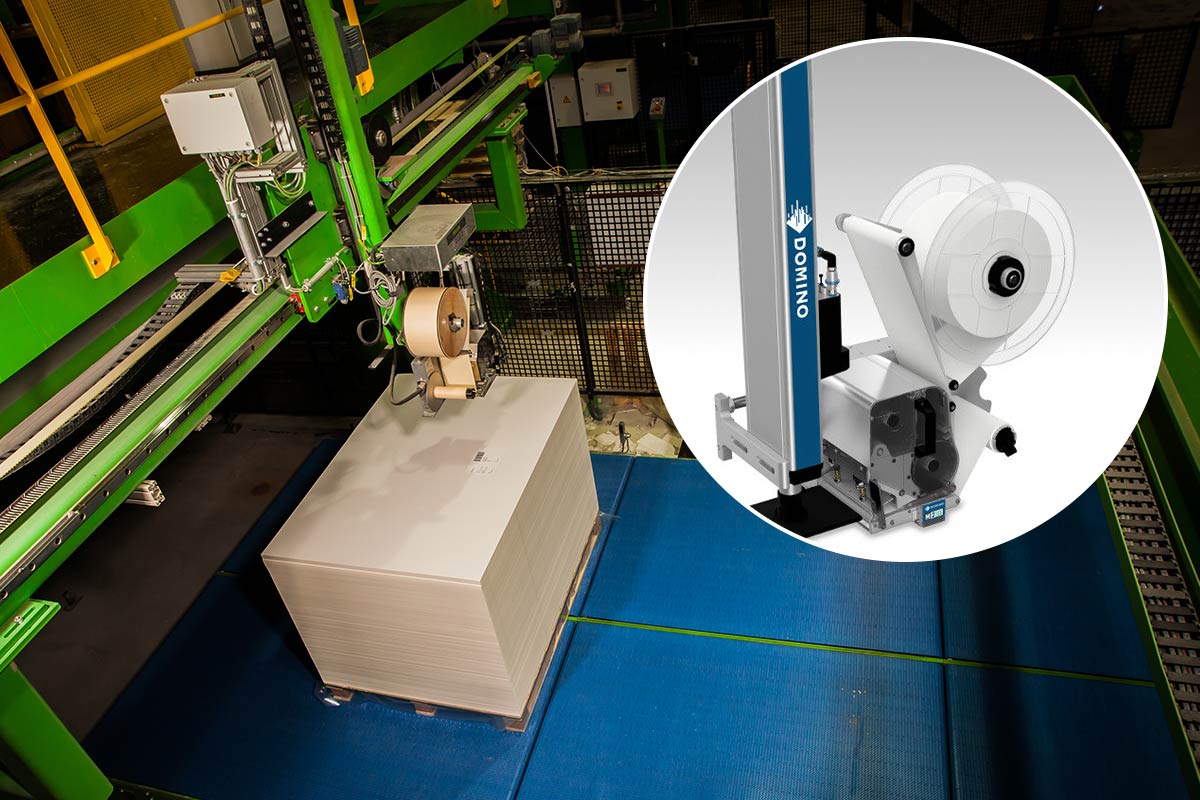

Print & Apply deliveries

In Print & Apply equipment, we use mass-produced thermal or thermal transmission printers in which the printer and affixing device are integrated into a single unit.

We also apply Print & Apply devices to applications in which a standard device is unsuitable. One example is a customised portal manipulator which extends the labelling device’s working area and the device is suitable for marking the sheet cutter’s set of pallets.