3D printing

3D printing

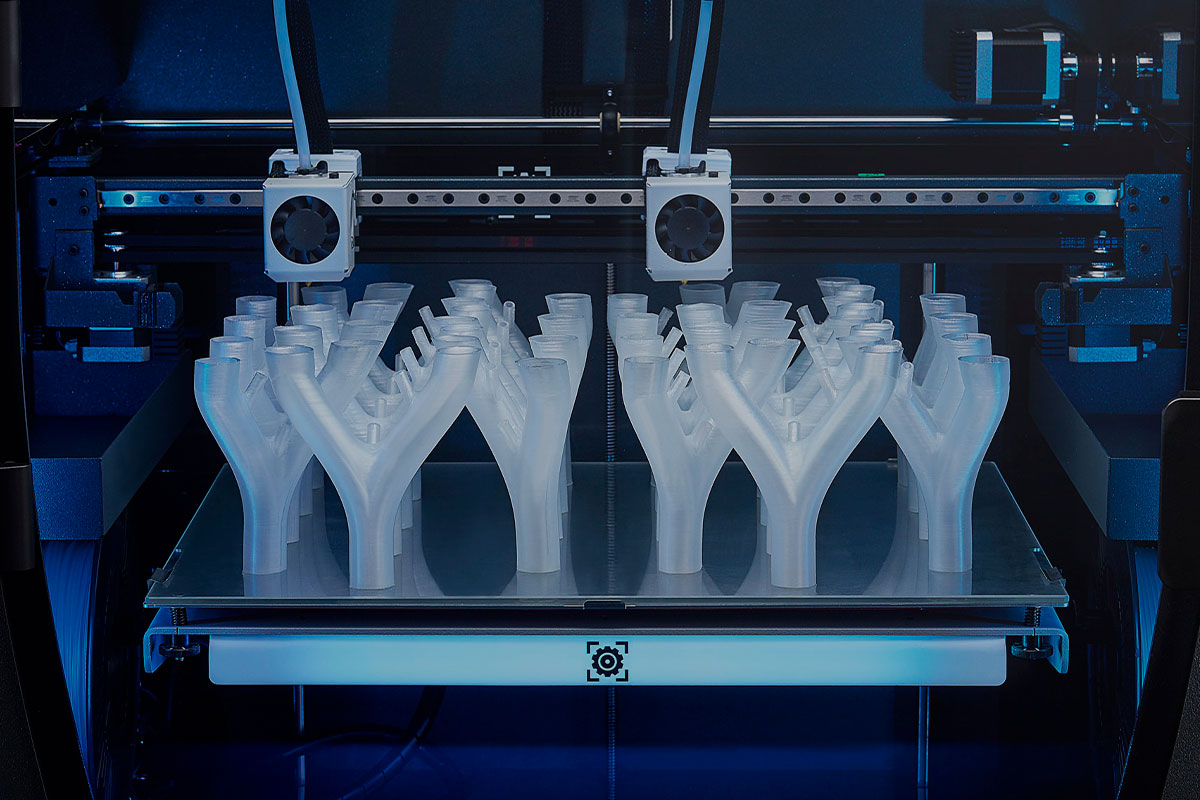

We use 3D printers to print technical plastics and carbon or glass fibre plastic composites. The printing area, or the heated bed, is 420mm x 300mm in size and the maximum height of the printed product is 200mm. The device contains two printing heads which can simultaneously print two identical components or one component and its mirror image, which the machine can produce without a separate model. The printing heads can also print different materials and be fitted with different-sized nozzles. One head can be used to print a water-soluble support structure while the other prints the actual component, for example.

The printed components can be prototype models or finished products. The advantage of 3D printing is the free design of components and the possibility of making hollow areas in components or e.g. ducting for pressurised air installations.

Various mountings, controls, pincers, etc. can be made quickly and flexibly.

Examples

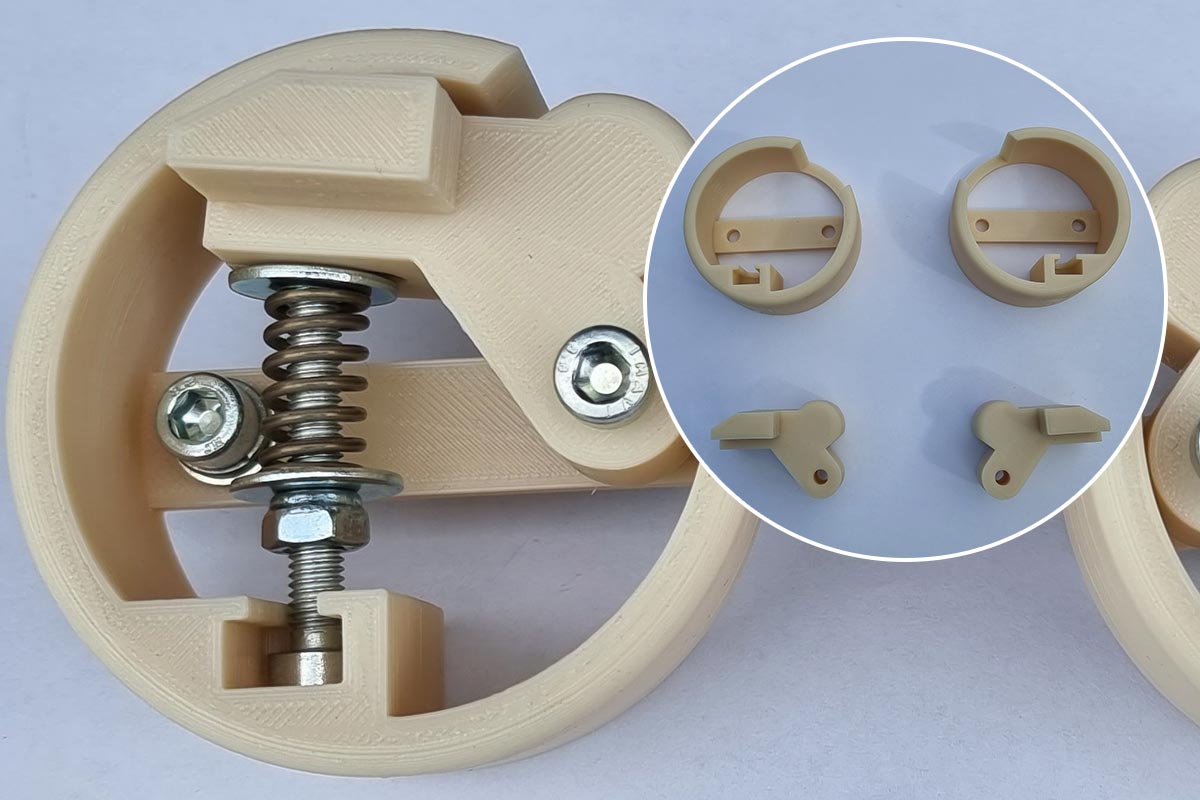

An example of a friction brake with components printed from ABS plastic. The mirror image components were printed automatically using the second printing head and only one set of components were modelled with a CAD program. All four components were printed overnight in just under 13 hours.

The 3D printer provides the freedom to design components for their purpose. To minimise printing time, it is best to only print material where it is needed for strength or functionality